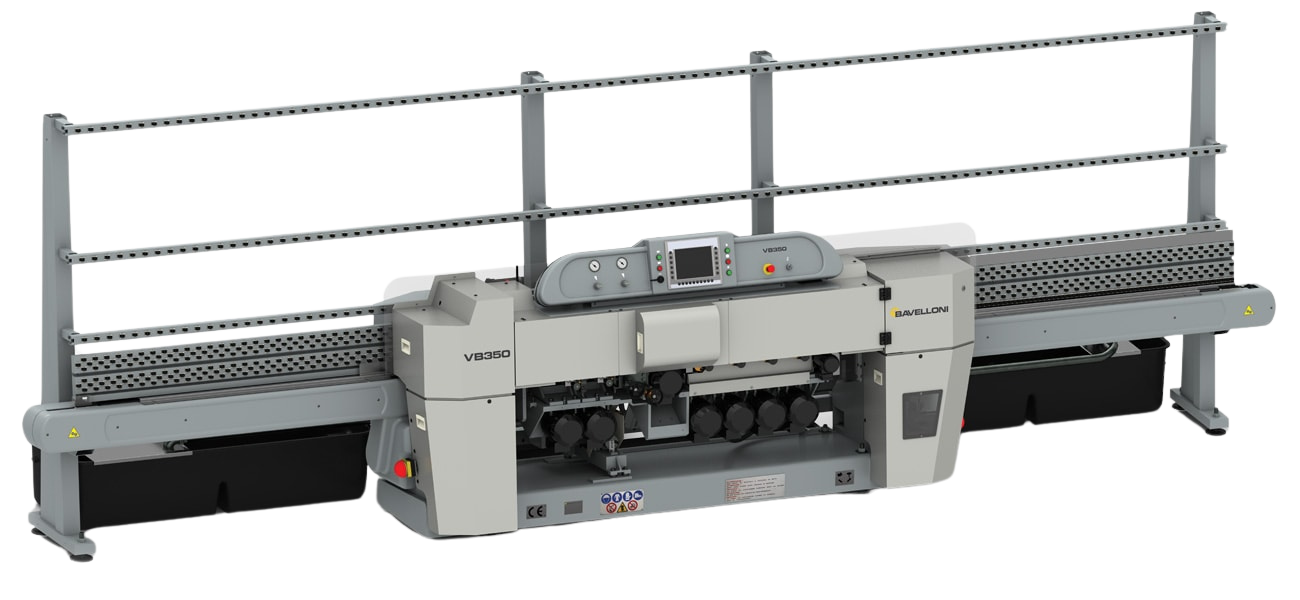

BEVELING MACHINES BAVELLONI VB 350CN&CNS

Brand: Bavelloni

Available on backorder

Bevelling machines for glass.

Technical features and options

- VB 350, the most popular bevelling machine, it is widely considered as the best compromise between level of investment and productivity. The VB 350 adopts all the technical features used on the top model, and it is an excellent choice for many companies: while operating at a slightly lower working speed, it gives a very good quality result and it allows to reduce investment and operating costs, being easier to use and less demanding in operation.

- VB 350 is produced in two configurations depending on how the edge remaining after bevelling is to be processed. The CN model is equipped with a wheel for grinding the front arris. The CNS version can grind the remaining edge with pencil edge shape using a peripheral diamond wheel.

- VB 350 grinding quality is excellent. In situations where high productivity rates are not essential, the Bavelloni VB 350 is the best solution.

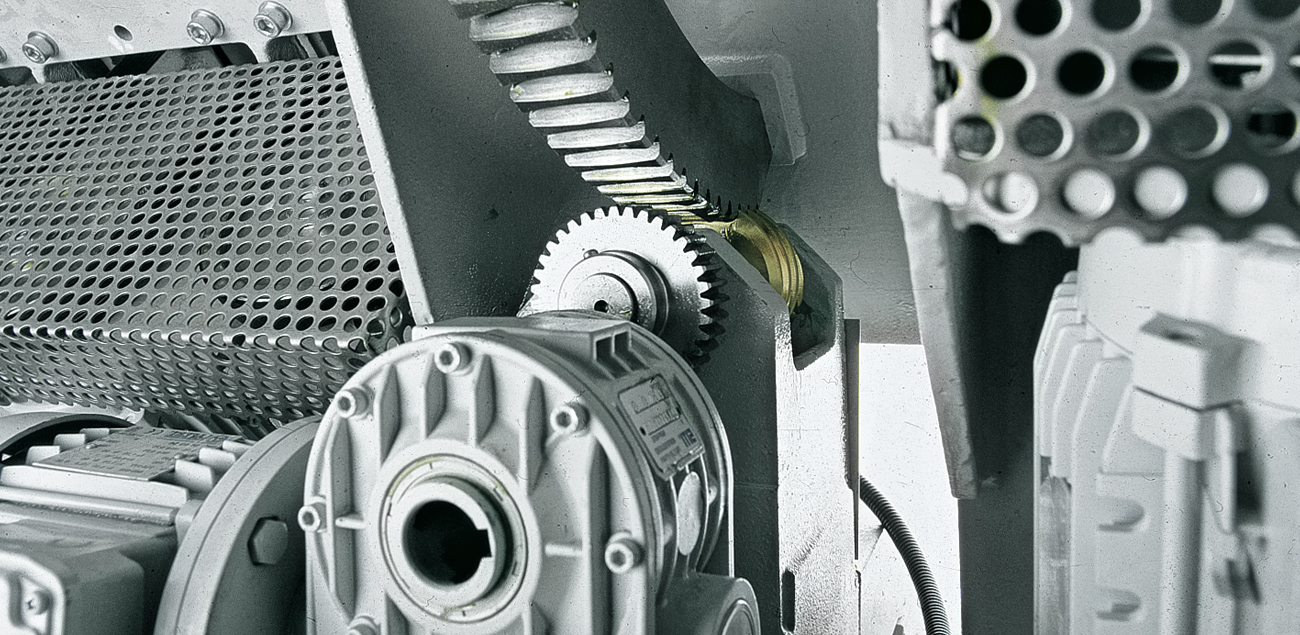

- Bavelloni’s patented conveyor, equipped with pads in cast-iron without the use of ball bearings, producing very high precision that is an essential element in bevel processing. The spindles are separated from the electrical motor by transmission belt eliminating vibrations and giving excellent grinding quality.

- The touch screen control panels of Bavelloni bevelling machines offer user-friendliness, flexibility and functionality. They can automatically perform calculations, report errors and prevent operation with incorrect parameters. The design of the work to be performed is displayed. Up to 99 different work configurations can be memorized; simple, double and triple bevels can be automatically set. The control panels offer an extremely precise digital visualization of the spindles absorption for perfect control of the machine.

- Bavelloni designed a unique device with extendable pads automatically activated by the control system for bevelling very small glass pieces.

See how it works

If you do today the same, how you did yesterday, you will have nothing to do tomorrow.

Innovation is in our DNA.