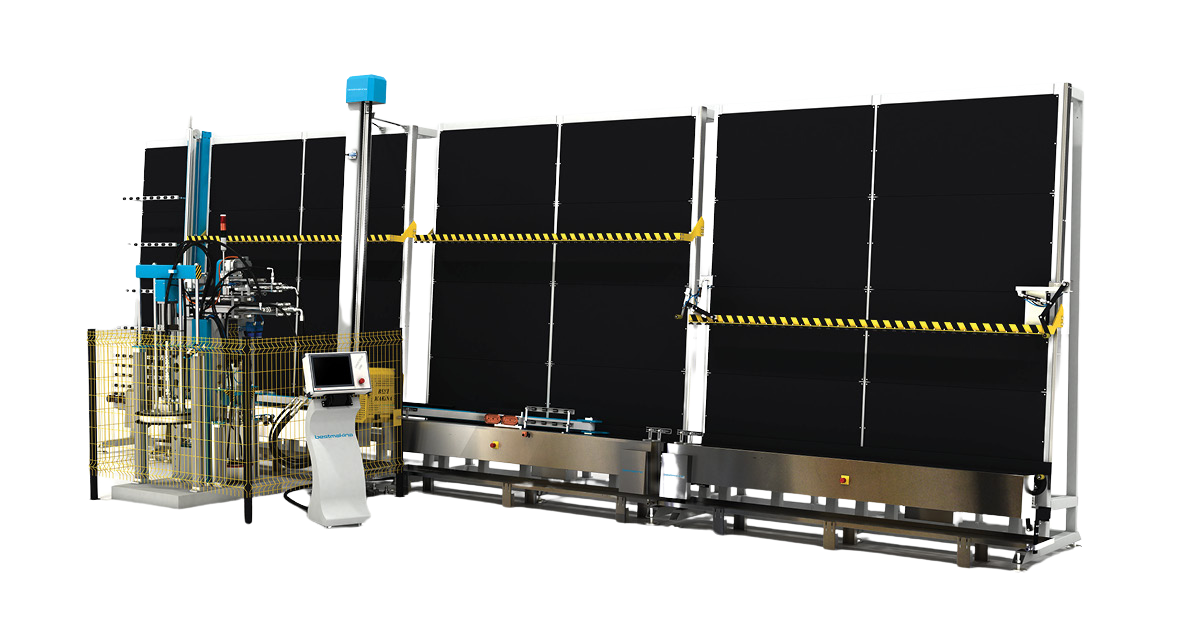

AUTOMATIC TWO COMPONENT EXTRUDER WITH SERVO MOTOR DRIVEN PUMP BESTMAKINA BLS-S

Brand: Bestmakina

Available on backorder

Automatic two component extruder with servo motor driven pump.

Technical features and options

• Material used: polysulfide, polyurethane, glazing silicone, structural silicone

• Automatic unit thickness – air space – sealing width detection with laser sensor

• Automatic unit height detection system

• Automatic flow rate adjustment system supported with servo motor drive for fast, continuous dosage adjustment

• Auto flow rate change for unexpected depth changes

• Unit holding and synchronized feeding system with vacuum cup

• Chain drive system for preventing sticking of sealant to conveyor

• Cleaning system for chains to keep system free from sealant

• Auto-flushing system for stand-by cases to keep mixing template safe against solidification

• High pressure solvent application for auto flushing

• Fast and accurate positioning CNC drive system

• Increased resistance for high pressure and chemical corrosion in main material pump

• High pressure and flow rate with servo motor drive

• Unlimited dosing range thanks to servo motor drive for different chemicals

• Users are allowed to use a variety of sealants as Polyurethane, Polysulfide or Glazing silicone

• Continuous flow for over size units

• Automatic corner cleaning

• Manual control of all commands

It is used for extruding polysulfide between sheets of insulated glasses automatically.

Options:

• Extra racks for oversize units

• Secondary pump system for second work

• Stepped unit sealing system

See how it works

If you do today the same, how you did yesterday, you will have nothing to do tomorrow.

Innovation is in our DNA.