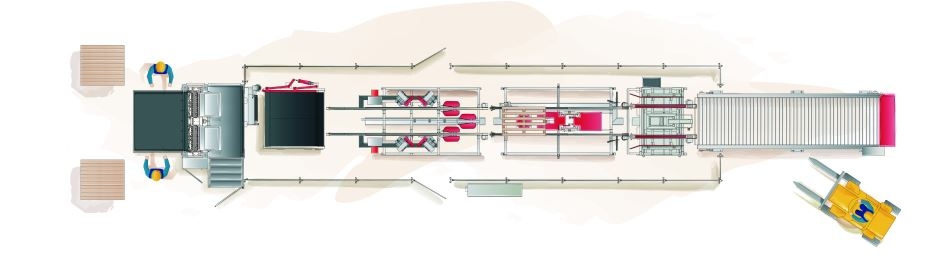

NAILING LINE FOR THE PALLETS STORTI GSI 150 AL

Brand: Storti

Available on backorder

Flexible system for pallet production. The nailing line with alternating carriages mod. GSI 150 AL has been designed to simplify the work of companies engaged in the production of pallets and decks, enabling them to obtain products of the highest quality, capable of satisfying their customers’ different needs. Efficiency depends on the pallet model, mostly 1,5 pallet per minute.

Technical features and options

Storti constantly improves the technologies used in its production lines and can provide its customers with a flexible, highly efficient nailing system, that offers advantages in many different aspects. More specifically, the main benefits include:

- High quality to price ratio,

- Possibility of producing different unfinished products simultaneously (on the same machine),

- Possibility of customizing the line,

- Quick changeovers to other sizes.

The example line includes:

- Nailer with carriage and steel beam hydraulically pressed model GSI 150 AL

- 1 basket + feeders for 12 nails

- 24 mechanically locked hammers

- pallet dimensions:

- length – max. 1500 mm

- width – max 1500 mm

- hight – min. 65 mm, max. 180 mm

- nail length – min 30 mm, max 100 mm

- Combined corner cutting, chamfering and labeling machine

- Pallet turntable 90 + 180 degrees

- Pallet stacking device – interlocking stacking

- Powered chain conveyor for unloading pallet stacks

Possible pallet dimensions are tailored to customer needs.

Each project is treated individually. Both the machines in the production line and their processing capabilities are tailored to the client to optimize their work as much as possible.

If you do today the same, how you did yesterday, you will have nothing to do tomorrow.

Innovation is in our DNA.