CNC BIESSE MASTER SERIES

Brand: Biesse

Master Series is the range of work centres dedicated to glass machining for the products that are typical of the furniture, automotive, building and domestic appliance sectors.

Technical features and options

It represents the best solution in terms of performance and productivity, and is suitable for high-speed machining of small and large production batches. The all-new and improved Master range maintains the quality and reliability that has always characterised Intermac technology, making it an industry-leading company and an iconic point of reference in its field.

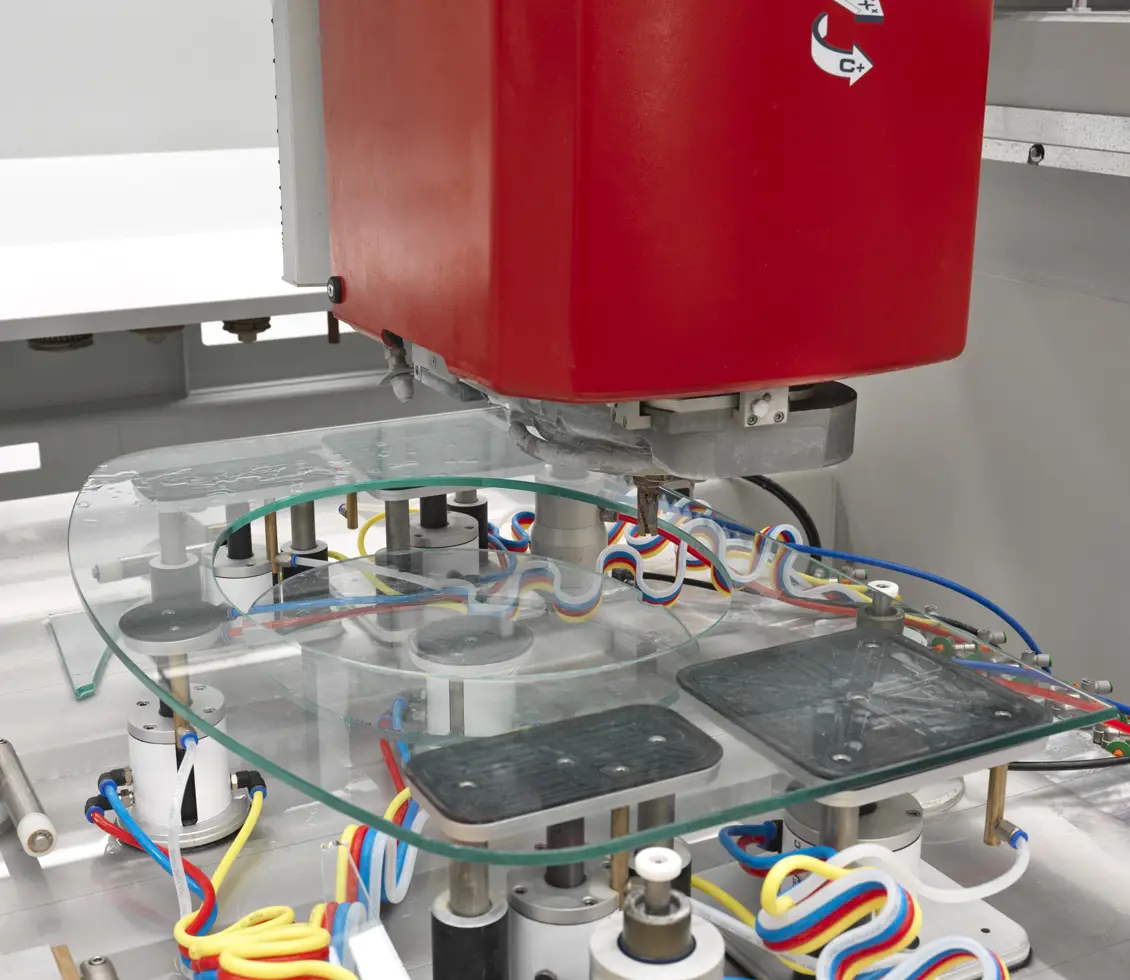

High-level technology for the best results with maximum ease of use. The 5-axis head with endless rotation C axis and tilting A axis (from -90° to +90°) ensures excellent flexibility and pushes the limit for the execution of complex machining operations.

The Master range guarantees fantastic performance thanks to the possibility of machining one or two glass sheets at the same time.

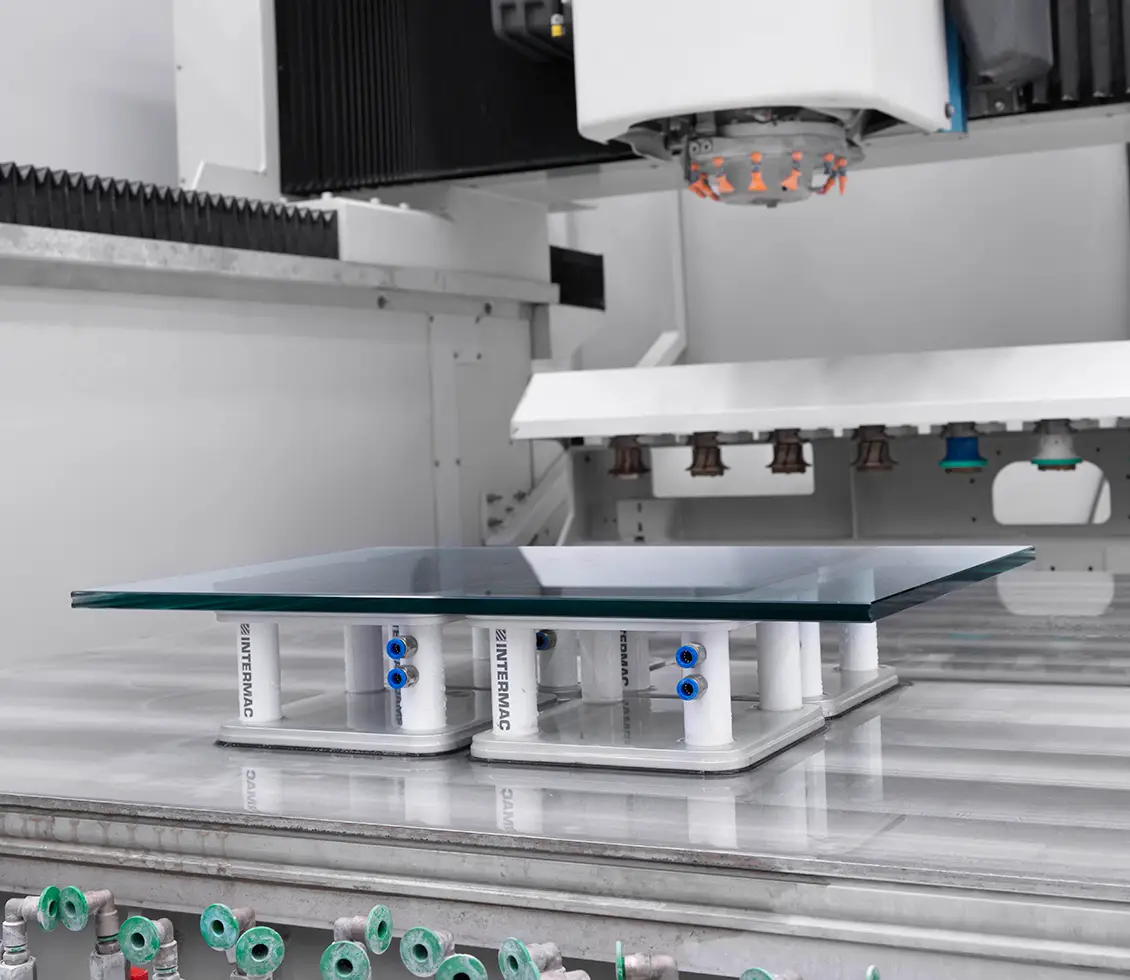

- The new generation of rectangular suction cups on all Master working centres – The new rectangular suction cups guarantee better vacuum retention compared to traditional suction cups, they are available in all versions and sizes and guarantee maximum customization flexibility.

- Matrix telescopic system – The MTS system can process various types of glass sheets of different shapes and sizes as part of a Batch One production process, with no need to worry about changing the positioning of the suction cups in the machine each time, thus enabling different sheets to be machined in succession.

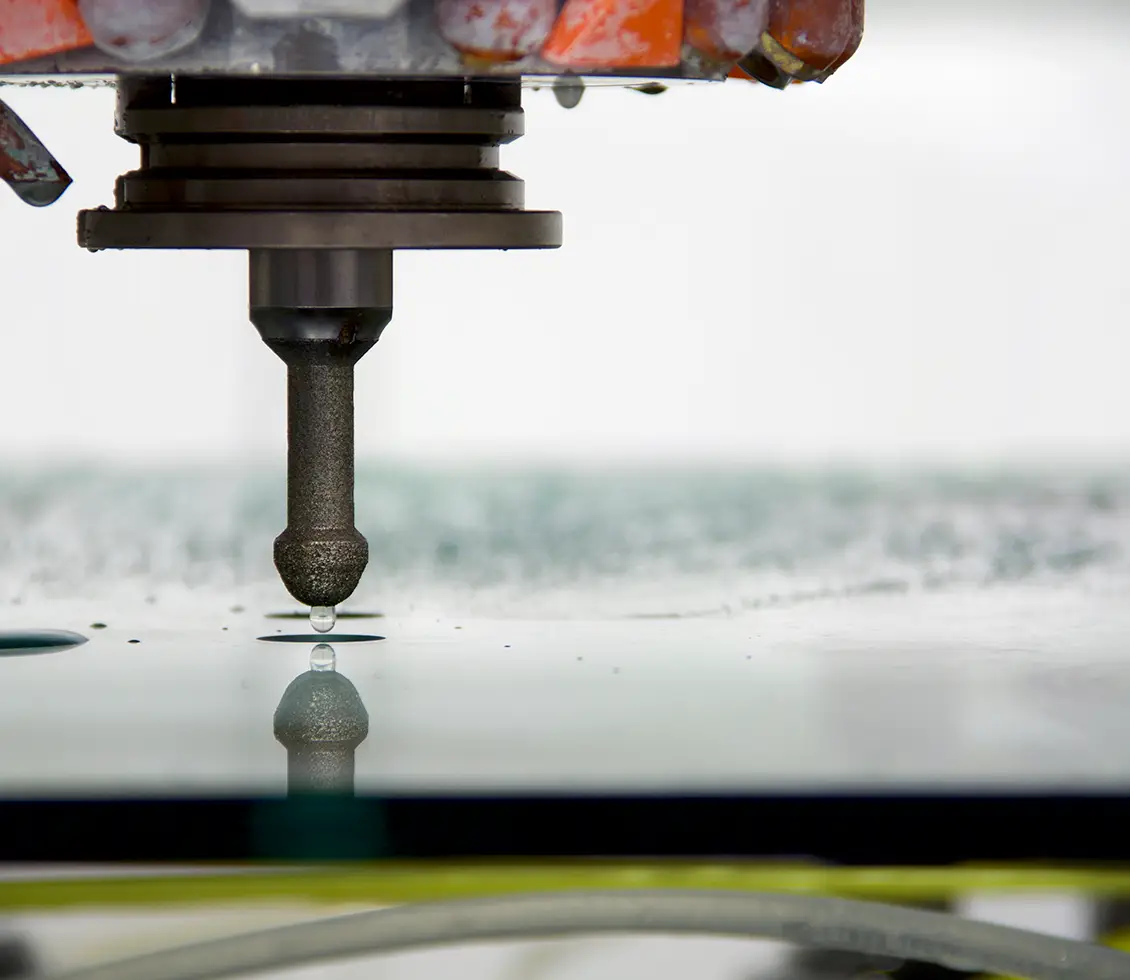

- Revolutionary boring – Helix is the Diamut tool that, when combined with software, exceeds all the limits of the traditional boring systems, using one single tool for all the boring, grinding and countersinking operations on glass sheets of up to 19mm.

If you do today the same, how you did yesterday, you will have nothing to do tomorrow.

Innovation is in our DNA.