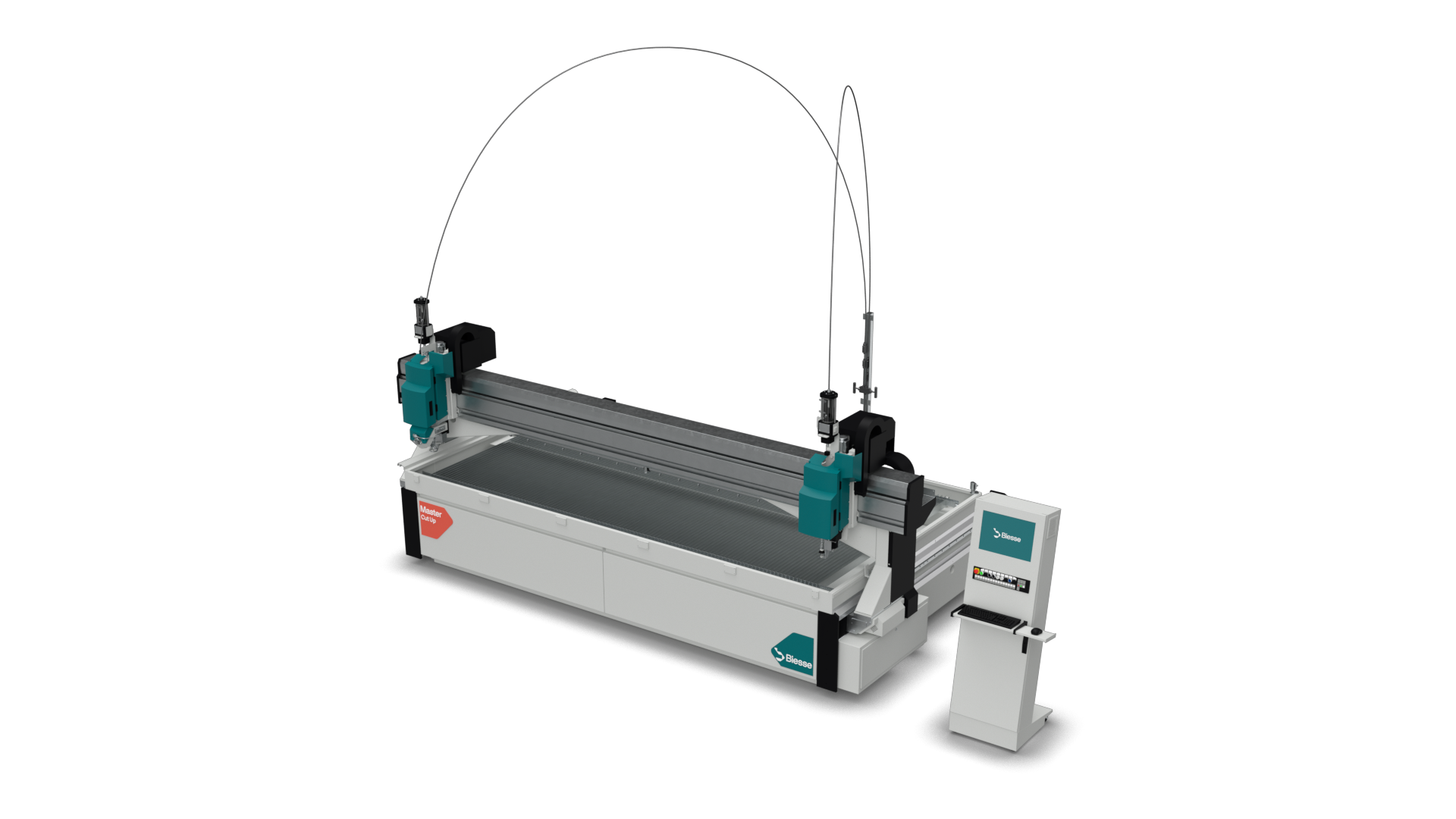

WATERJET BIESSE MASTER CUT UP J O P

ID: 6858

Brand: Biesse

Stock status: to be ordered

The Master Cut Up J O is a versatile waterjet system featuring an expanded working area and the option for a dual cutting head, nearly doubling productivity. It is ideal for industries that require flexibility and high output.

The Master Cut Up J O is a versatile waterjet system designed for businesses that require a flexible cutting solution. Equipped with a 5-axis cutting head, it delivers highly accurate and complex cuts with ease. Its advanced abrasive management system enhances performance while reducing waste, making it an ideal choice for industries that demand both flexibility and high productivity.

Technical features and options

| MODEL | 322 | 402 |

|---|---|---|

|

Cutting area |

3210×2000 mm |

4000×2000 mm |

|

Support piece |

3300×2250 mm |

4100×2250 mm |

|

Max Z axis stroke |

200 mm |

200 mm |

Machine configuration possibilities:

- 5-axis endless rotation titling head (+/-60°).

- High Pressure Pump – BFT ECOTRON 40.37 (50 Hp) 37kW Air Cooling.

- 330kg pressurized abrasive feeding system and automatic abrasive flow.

- Thickness probing device to detect variable work piece heights.

- DDX EasyStone CAD/CAM programming software for 5axis water

- Double cutting head.

- Loading tilting arms.

- Presetter for automatic 5-axis alignment.

- Camera for material detection.

- Front rollers for loading slabs.

The Master Cut Up J O is a versatile waterjet system offering a larger working area and the option to install a dual cutting head, nearly doubling productivity. It is ideal for industries that require flexibility and high output.

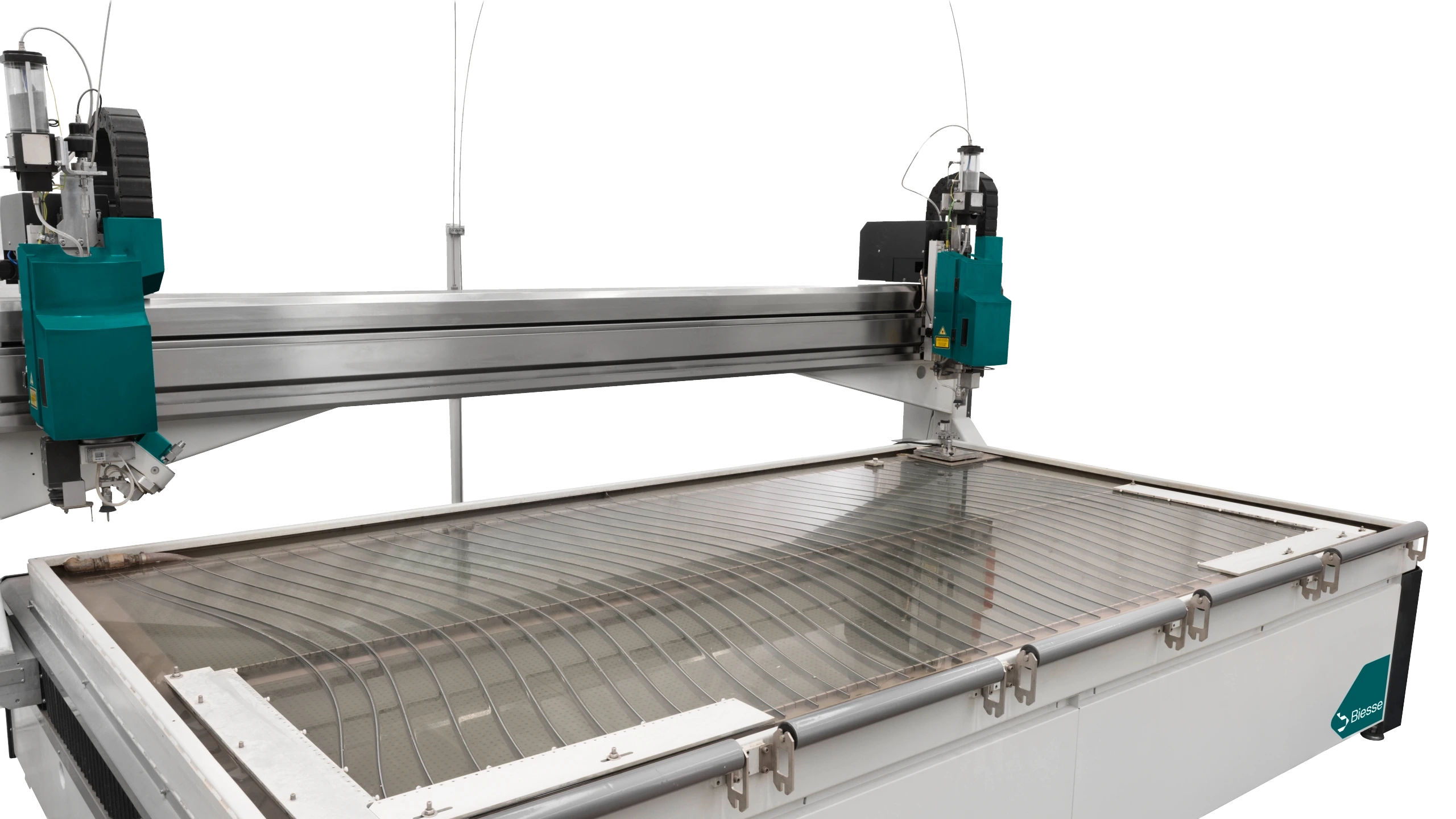

Unleash precision with 5-axis power

Maximum programming flexibility thanks to the free movement of the cutting head.The 5-axis cutting head is fitted with the patented Intermac infinite rotating C axis system for making top-quality tilted cuts (+/-60°) on complex profiles, with no limits. This system eliminates the errors due to rotating axis reverse clearance in traditional methods, and also guarantees a constant supply of abrasive material.

Easy loading with tiling arms

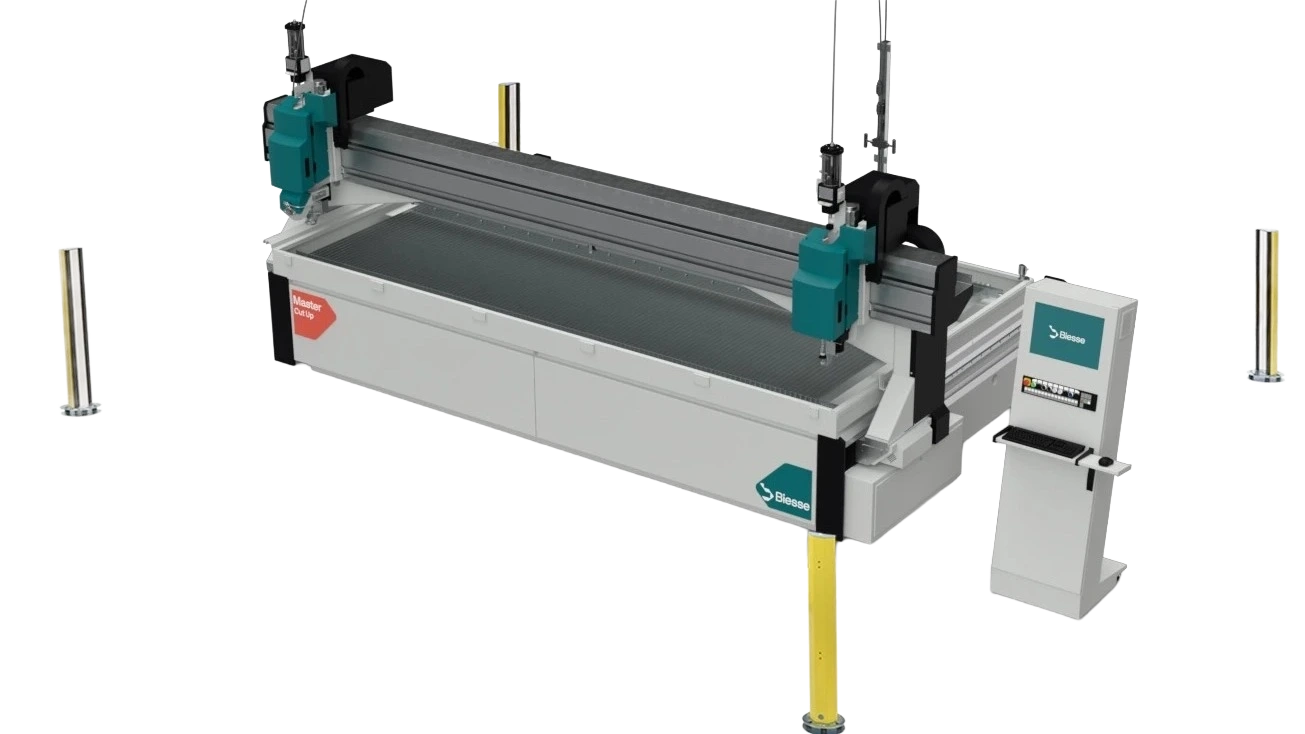

Twice the Speed. Twice the Precision. Double the Performance.

The Master Cut Up J O can be configured with one or more independent cutting heads, depending on the customer’s production requirements.

Instant readiness: just start cutting

The Master Cut Up J O eliminates the need for suction cups and tool setup, making it ideal for prototyping and small batch production while still delivering high productivity.

Natural stone, sintered materials and ceramic stone

The Master Cut Up J O is ideal for cutting kitchen countertops with 45° angles, allowing pieces to be seamlessly joined to create complete kitchens, including backsplashes and splash guards.

Safety-First Interaction

he Master Cut Up J O is equipped with advanced preventive safety features that protect the operator from collisions while still providing easy, unobstructed access to the machine.

If you do today the same, how you did yesterday, you will have nothing to do tomorrow.

Innovation is in our DNA.